Home Wiring & Rewiring Services

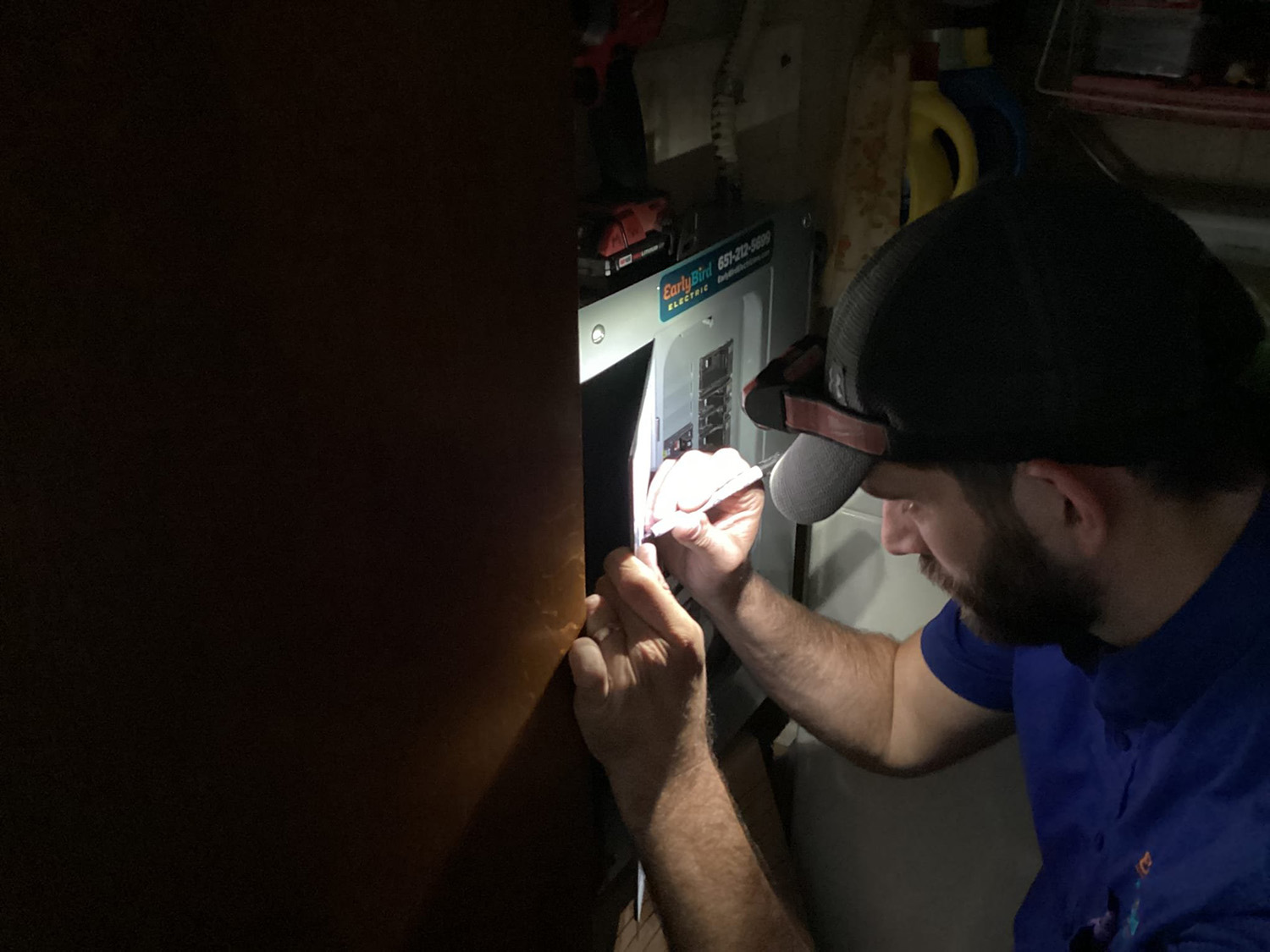

EarlyBird Electric has been the trusted name for home electrical services for the Twin Cities and surrounding area since 2013.

Get Started Now

Schedule Your Appointment Online Today!

EarlyBird Electric has always been focused on ensuring your family is comfortable and safe by keeping your home’s electric systems in good working order.

- Certified, experienced professional electrician to serve all your home electrical needs

- 24/7 emergency repair service to prevent damage to your home

- Fully stocked electric service and maintenance vehicles so we have what we need

- Prompt, friendly service throughout the Twin Cities and beyond

- Backing what we sell with warranties and fast responses

- Money-saving Legendary Care Club preventive maintenance programs

- Your satisfaction is 100% guaranteed

Home Wiring & Rewiring Services From Earlybird Electric

Building a new home or adding onto your current home in the Minneapolis – St. Paul area? You want to be sure you’ll have safe and reliable electric service. That’s where the wiring professionals from EarlyBird Electric can help. Whether you need wiring for a new room or structure or want to upgrade your home or building’s existing wire to today’s code and standards, they’ll be happy to help.

Contact us today to schedule your home wiring or rewiring service and let us help keep your home’s electrical systems problem-free.

Electrical Repair Overview

Legendary Care Club Maintenance Program

Properly maintaining your home’s electrical, heating, cooling, and plumbing systems keeps them operating efficiently and safely, reducing the potential for breakdowns and repairs. We offer a variety of maintenance options that also include priority service and discounts.

Learn more

Affordable Financing Options

Money shouldn’t stand between your family and a safe, comfortable home. That’s why we’re happy to offer a variety of financing programs that give you ways to enjoy safe and reliable electrical products and systems through affordable monthly payments. Ask us for details!

Learn more

24-Hour Emergency Repair

EarlyBird Electric provides emergency electrical repair service 24 hours a day 7 days a week. We come to your home day or night to take care of any power-related emergencies. Our certified electricians will quickly pinpoint and repair the problem.

Learn more

Upgrade Electrical Panels

If you’re still dealing with the hassles of blown fuses or never seem to have enough electricity to meet your family’s needs, let the certified electricians from EarlyBird Electric recommend upgrading to a state-of-the-art electrical panel and 200-amp service.

Learn more